hardness test requirement|iso 6508 pdf free download : distributor The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers Hardness

Resultado da guerreiro777 MANUAL: R$ 360,00: 09/12/22 09:14:15.382: thaynaralim MANUAL: R$ 320,00: 09/12/22 09:13:16.993: bruta AUTO: R$ 300,00: .

{plog:ftitle_list}

Resultado da 🔗 https://game.today777.com/#/ 🚀 Conta oficial da Today777 TG 🎰 Uma variedade de jogos para escolher 🎁 Várias atividades de bônus em .

Measuring hardness has a number of benefits in comparing materials and providing quality control in manufacturing and hardening processes. This article will discuss hardness testing, its definition, how it works, its types, .Standardized optical hardness testing methods include the Brinell hardness test (ISO 6506, ASTM E10), Knoop hardness test (ISO 4545, ASTM E92, ASTM E384) and Vickers hardness test (ISO 6507, ASTM E92, ASTM E384).Hardness Testers for all scales by INNOVATEST. Hardness testers are devices for measuring and/or testing the hardness of metals and plastics. INNOVATEST offers a comprehensive range of hardness testers for all scales, including .

The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; .

Requirements for Brinell Hardness Testing. Before the test, the sample must be cleaned thoroughly. Preferable if the test surface is machined, ground, and polished to get better indentation measurement. Proper indenter (Steel ball or . The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers Hardness

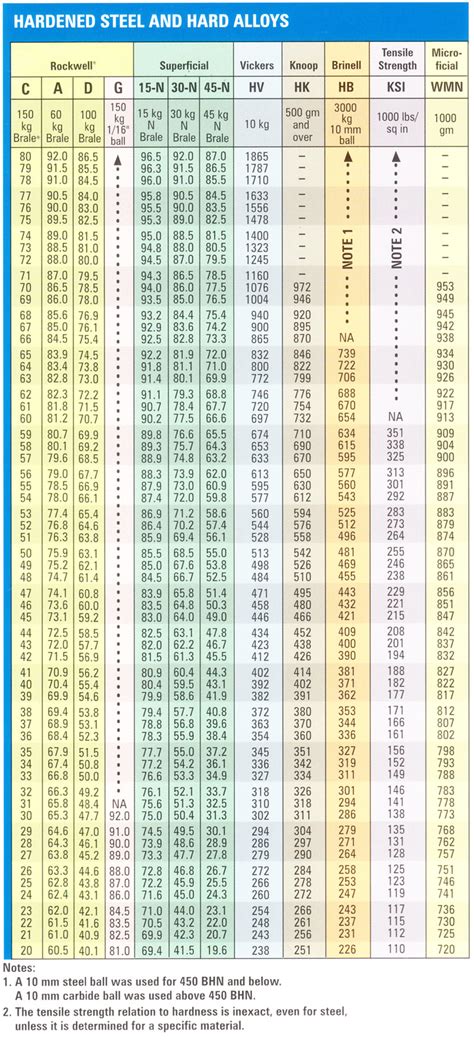

Guides to Hardness Testing. Hardness Conversion for Rockwell C Scale or High Hardness Range . Minimum Thickness Requirements Guide Roundness Correction Factors Rockwell Hardness Testing Reference Guide .

The Janka hardness test (English: / ˈ dʒ æ ŋ k ə /; [1] German:), created by Austrian-born American researcher Gabriel Janka (1864–1932), measures the resistance of a sample of wood to denting and wear. [citation needed] It measures the force required to embed an 11.28-millimeter-diameter (7 ⁄ 16 in) steel ball halfway into a sample of wood.(The diameter was chosen to .Influential in the development of hardness testing standards in ISO and BSI, as well as ECISS, Foundrax remains at the forefront of Brinell test machine development through continuous research. Foundrax offers a range of Brinell hardness testers covering every industrial requirement, providing market-leading automation of both indentation and .The welding variables are recorded during welding of the test piece and hardness testing is mandatory, the hardness of the test weld HAZ to be less than 248Hv10, that of the weld metal less than an average of 200HBW. Hardness testing surveys are as described in NACE MR0103.

Each hardness testing method has its benefits and will allow for the precise measurement of material hardness in accordance with the technical specifications of the hardness testing instrument. . In order for the measurements to be reliable and accurate, certain requirements must be met. These include ensuring that the hardness tester .The 574 Series Wilson Rockwell Hardness Testers offer quality, durability, and an industry leading Gauge Repeatability and Reproducibility (GR&R) making this hardness testing machine best in class. This system is available in Regular or Twin Scale models and capable of testing in all of the regular and superficial Rockwell hardness scales and .Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from Struers, the world’s leading materialographic and metallographic experts. . The required surface condition for the .

There are 7 main types of hardness testers. Hardness testing is the procedure of testing the hardness characteristic of a material so properties such as strength, wear resistance, and ductility can be determined! . An advantage of the test is that only a small sample of material is required. It is also valid for a wide range of test forces.Hardness testing is used for two general characterizations 1.Material Characteristics . On small parts, it is particularly important to be sure to meet minimum thickness requirements and properly space indentations away from inside and outside edges. Larger parts need to be fixtured properly to ensure secure placement during the test process .Buehler offers complete hardness testing solutions with hardness testers, hardness test blocks, and Buehler designed hardness testing software. . both the UH4250 and UH4750 models focus on fast and simple operation while maintaining the complexity of features required by expert users. Features include an optional clamping tool for stability .

Hardness testing to Brinell is mainly performed with HBW 1/30 or HBW 2.5/187.5. For hardness testing to Rockwell, scale B (HRB) is used for fasteners of property class 4.6 - 6.8 and scale C (HRC) for property classes 8.8 - 12.9. .Portable Leeb Hardness Tester Kit with Test Block,Hardness Testing Equipment,Rockwell Metal Hardness Meter Durometer for Steel,Aluminum Alloy,Copper,7-in-1 HL, HV, HB, HRC, HRB, HRA, HS 9.98 $ 199 . 98

Note: Exception to the following hardness testing requirement is granted for small complex geometry parts which, as a result of geometry do not allow for proper testing set-up or are subject to degradation as a result of testing. Engineering definitions that require hardness testing of .The set of Elcometer 3080 Hardness Testing Pencils is a simple but effective technique to evaluate the hardness of many coatings. The pencil lead, prepared beforehand by using the special pencil sharpener and rubbing it on fine abrasive paper (400 grade), is maintained at an angle of 45° and pushed with uniform pressure on to the sample, leaving either a superficial . Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, known as the .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.

The Wilson BH3000 Brinell Hardness Tester stands as a robust Brinell hardness tester, boasting a wide range from 62.5 kgf to 3000 kgf. Crafted with rugged construction for resilience in challenging environments, this reliable hardness tester blends high rigidity and closed-loop load cell technology to ensure precise and secure load applications.A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.Learn how to use Brinell hardness test units and testing machines to quickly and accurately assess large samples with a coarse or inhomogeneous grain structure – with knowledge and insight from Struers, the world’s leading materialographic and metallographic experts. . Optical reading required; Standards: ASTM E10, ISO 6506, JIS Z 2243 .

The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1/16, 1/8, 1/4 and 1/2 in. diameter steel ball indenters.Universal hardness testers are designed for hardness testing according to Brinell, Vickers, Rockwell and Knoop, as well as plastics testing and carbon testing.To cover all of these test methods, the universal hardness testing machine supports a wide load range. ZwickRoell universal hardness testers therefore provide a flexible solution with a load range from 0.3 to . If hardness conversion is used, procedures should address the conversion method as well as the requirements of paragraph 3.5.3 of AC7102/5, which requires that hardness test reports show both the measure value as well as the converted value.

How to use the Taylor R-0012 water hardness test kit - drop count titration method. This water hardness test method uses a water hardness reagent, an organic chelant solution whose principal ingredient is Ethylenediaminetetra- 60-00-4 <5 Irritant acetic acid.

rockwell hardness testing chart

rockwell hardness tester diagram

iso 6508 pdf free download

LIVE sports betting today: ⭐ Watch live broadcasting online ⭐ Live results ⭐Match statistics ⚽ MelBet Canada — Official website melbet-ca.com.

hardness test requirement|iso 6508 pdf free download